Why choose plastic agricultural bins? |BCE

What are plastic agricultural bins?

For decades wooden crates and boxes have been the collective standard for fruits, vegetables, and other food-grade applications. Over time, stricter regulations and standards have been passed. Those older wooden boxes and crates now are being phased out and replaced by plastic, durable agricultural bins.

Agricultural plastic containers are extremely durable - made from injection-molded, FDA-approved materials - and are lightweight. The injection molding process eliminates the need for nails and creates smooth, non-porous surfaces. Additionally, it eliminates the possibility of damaging and contaminating products with splinters. The smooth, non-porous surfaces reduce the risks of bacteria, contaminants, or insects. Vented harvest and solid wall bulk bins are made of 100% polypropylene material, so they're recyclable when they reach the end of their life cycle.

Are all agricultural bins the same?

Two types of agricultural bins that are commonly used: vented harvest bins and solid wall bulk bins. Both versions are made from the same injection-molded, FDA-approved plastic.

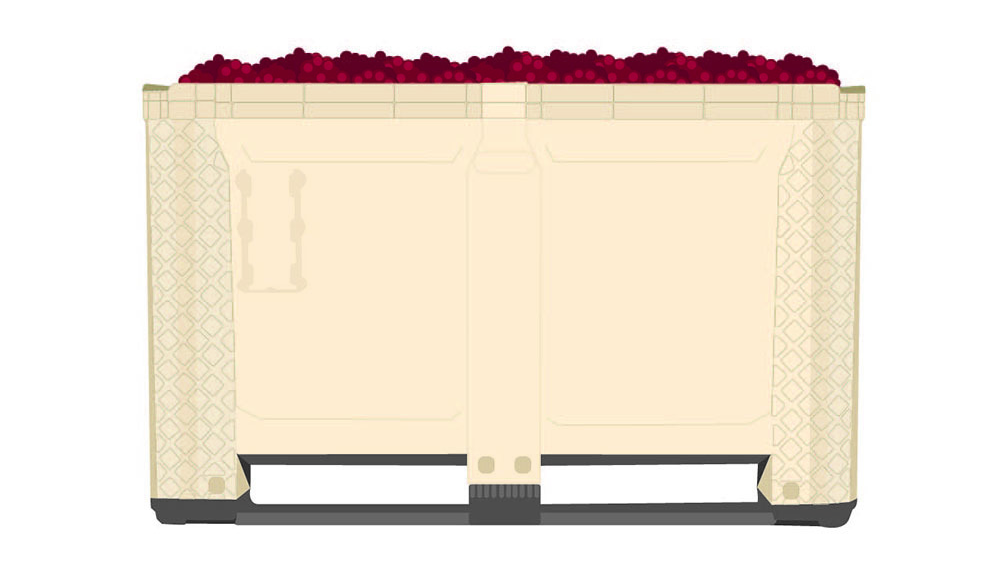

Solid wall bulk bins

These bins are made from FDA-approved plastics, making them ideal for food processing, agricultural, pharmaceutical, wine processing and industrial applications. They're engineered to meet USDA guidelines for sanitation and easy cleaning. Additionally, they're durable, splinter-resistant, and lightweight. These bins feature walls with a solid construction designed to keep contents of any size from falling out of the bin. Bulk bins come in a variety of sizes to suit nearly any material handling need.

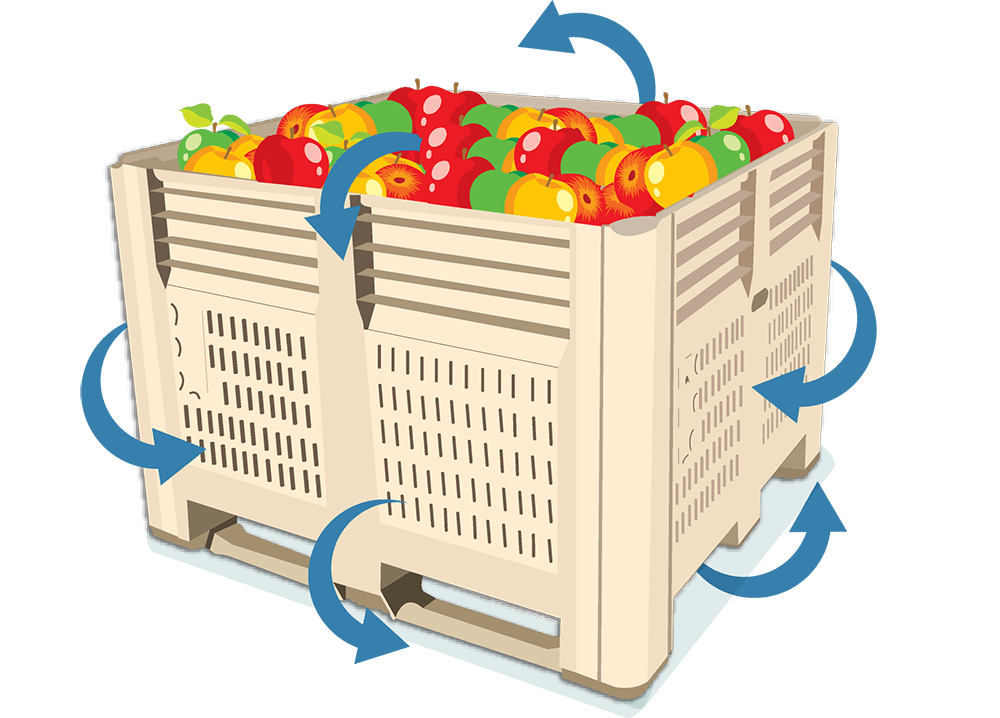

Vented harvest bulk bins

Vented harvest containers are constructed with smooth plastic surfaces, which can be easily cleaned to meet strict food safety requirements. The polypropylene construction also ensures the necessary unmatched durability and reliability to handle a variety of produce. Each of our harvest bins features industry-leading venting. These vents allow airflow through the container to ensure fruits and vegetables are appropriately cooled; they also facilitate improved storage in controlled atmosphere (CA) rooms for apples and other sensitive produce.

Other uses for solid wall and vented harvest bins

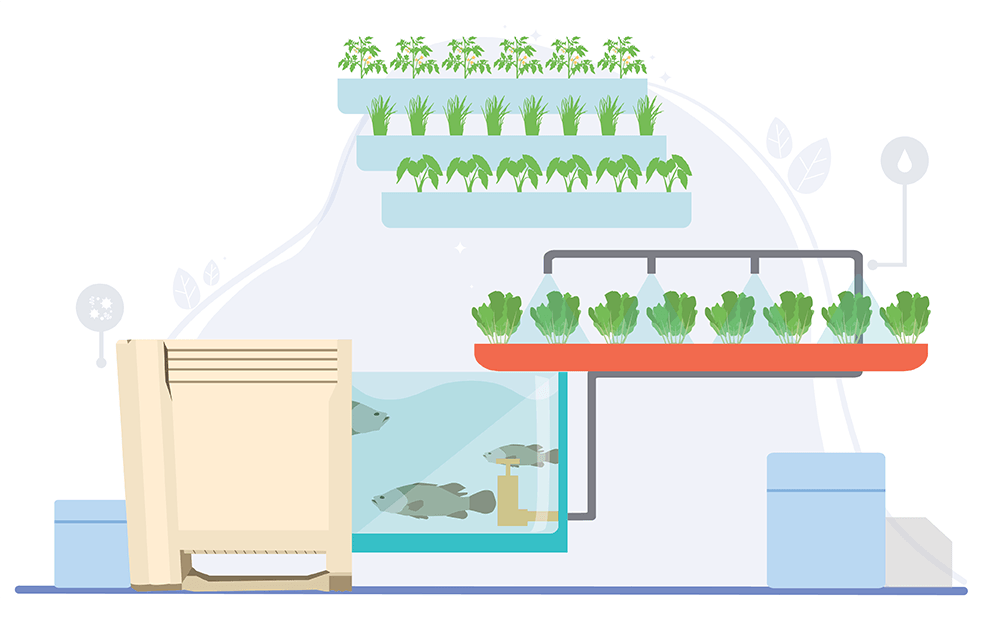

Solid wall and harvest bulk bins were created for transporting and storing fruits and vegetables, but they also work well for other food products like fish and meat. Solid wall bulk bins have recently grown in popularity in the aquaponic industry.

What are the benefits of using vented and solid wall bulk bins?

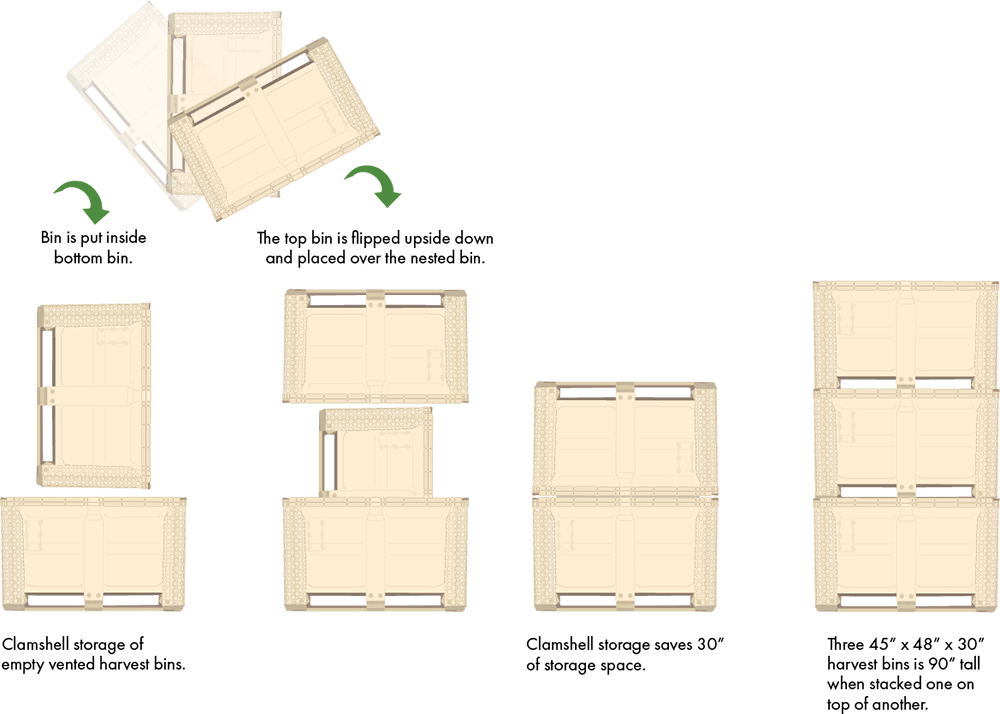

Efficient clamshell storage

When you're finished using vented harvest or solid wall bulk bins for the season, you can easily stack and store the containers when not in use to save space at your facility via the clamshell method to stack and store the vented and solid wall bulk bins. Place one bin on it's side and place it inside the bottom bin. The top bin is flipped upside down and placed over the nested bin.

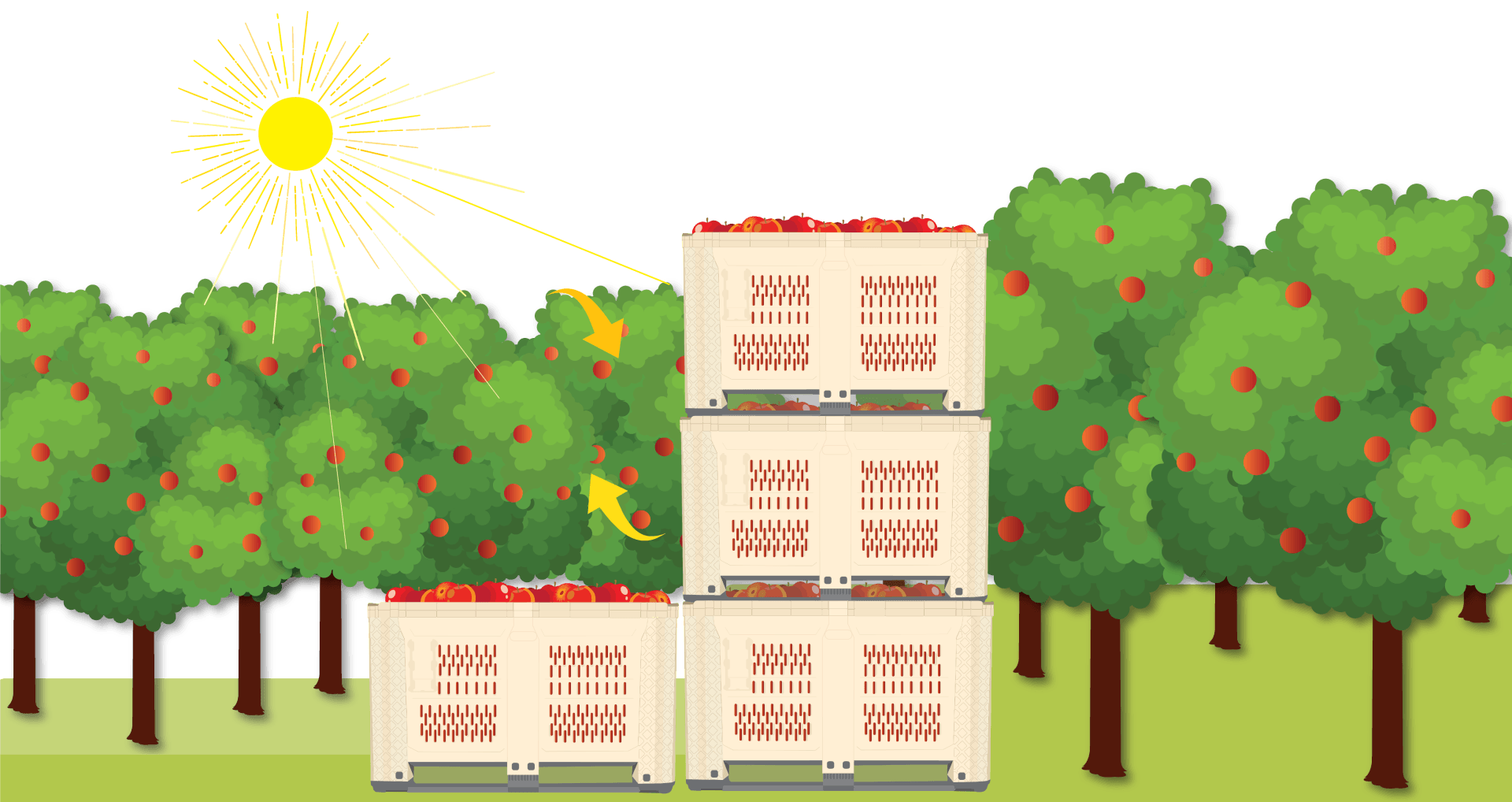

Temperature controlled

Designed with temperature control in mind, you won't need to worry about your crop overheating in the hot sun during the harvesting process. The light color of the bins reflects sunlight and, in turn, will absorb less heat, which keeps your product from getting too hot. Vented and solid wall bulk bins can also withstand the cold temperatures of processing facilities and refrigerated storage.

Secure, safe stacking

While harvesting, it's beneficial to be able to stack your full containers on top of one another to save space. The bases of the solid wall bulk bins have feet designed for stacking so a container can safely and securely be stacked on top of the container below without damaging any product. Our solid wall and vented containers can stack with or without a lid.

Do you have questions?

If you would like to learn more about harvest bulk bins or solid wall bulk bin visit the pages of our website or call 1-800-257-5560 to speak with an account manager.