What makes Pallet Packs Unique?

What is a Pallet Pack Container?

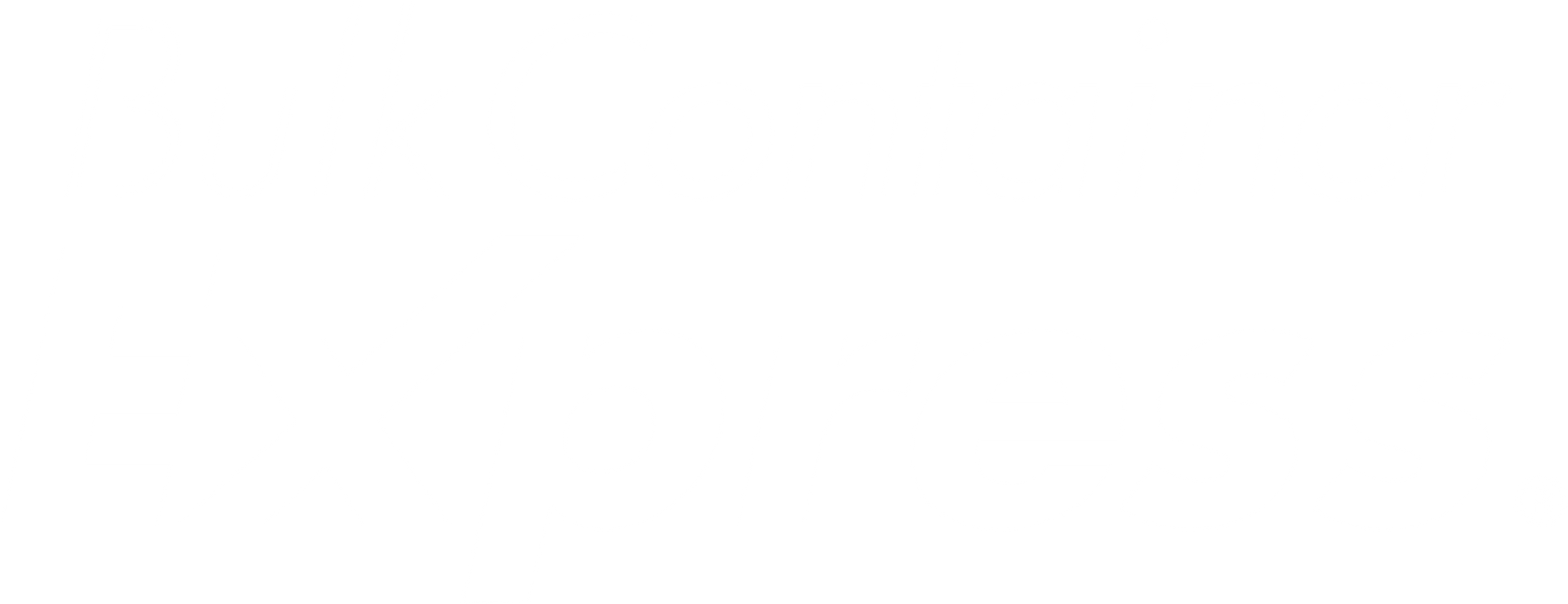

DuraGreen Pallet Packs are unique containers that can be used for many different applications. Each pallet pack container consists of three parts per unit: a plastic pallet, a plastic top, and a sleeve. The sleeve is available in either a corrugated cardboard option or a corrugated plastic option, and there are different footprints and heights available in each size.

The Corrugated Sleeve Option

With a heavy-duty, triple-wall corrugated sleeve, the corrugated cardboard sleeve can hold twice as much vertical weight as the corrugated plastic sleeve. When assembled, the cardboard pallet pack sleeve container option can hold 2,000 lbs. per container, and most sizes can stack four units high at full weight capacity. Even though it is made from a cardboard material, this sleeve is insanely strong! The only downside to this sleeve option is that it will act like cardboard when exposed to the elements. It is another option for you if you are in high humidity settings or if they are stored outside and exposed to the elements.

The Plastic Sleeve Option

The plastic sleeve option is made from a durable triple-layer polypropylene material. When fully assembled with the top and pallet, this container can hold up to 1,000 lbs. per unit, and most sizes can stack up to four units high. If you are storing your containers in high humidity or out in the elements, this is the better sleeve option when compared to the cardboard sleeve. Please keep in mind that there are still nooks and crannies from where the sleeve meets the top and the pallet, so if the elements are really acting up, this container will not be a waterproof option.

What about the pallets and tops?

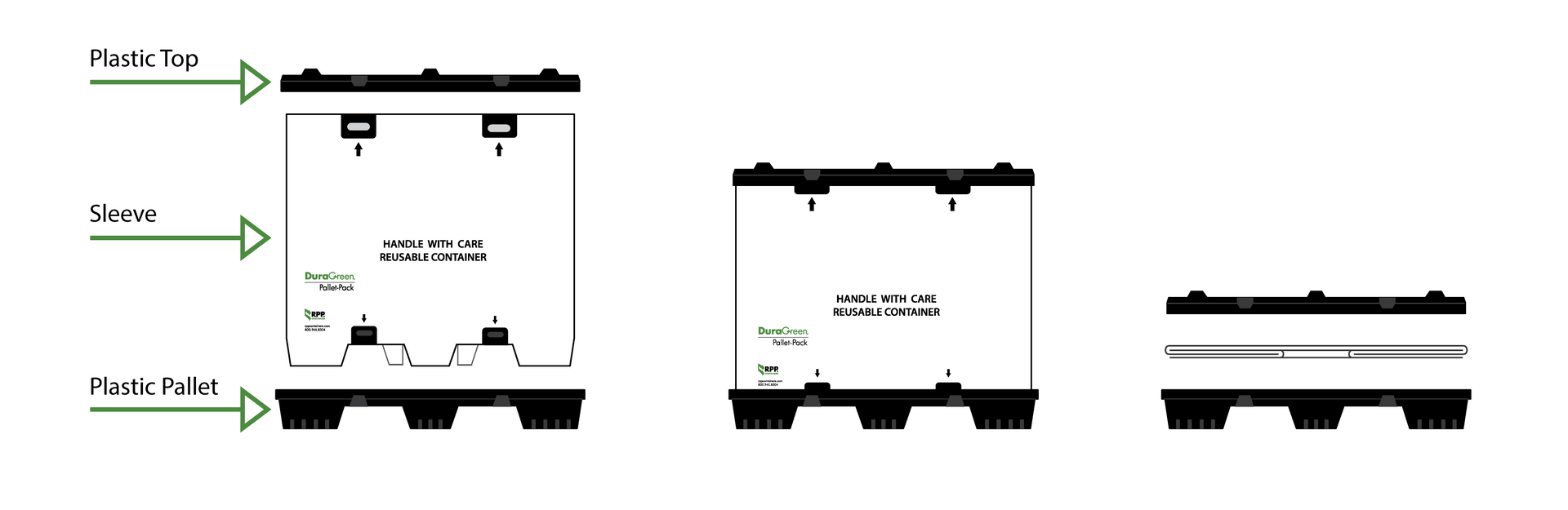

The plastic tops and pallets are made from a twin-sheet, thermo-formed plastic. The pallets and tops have up to a 10-year life expectancy, whereas both sleeve options will get approximately 50-100 uses. The tops and pallets are nestable with each other, and the sleeves are collapsible, which makes for a great return ratio. Since these containers are lightweight, just one person can assemble and disassemble a unit.

What are Pallet Packs most common applications?

Some popular applications for cardboard and plastic corrugated sleeves are soft goods and textiles. These containers are not appropriate for flowable materials, such as resins. Regardless of what is stored in the containers, you must have all three components (top, pallet, and sleeve) when using the container. It is also very important that the load is centered on the pallet and not leaning against the sleeve walls of the container, or else the container could fail when not used properly.

What are the Pallet Pack footprint options?

Our stock footprint sizes are 40” x 48” and 45” x 48” with varying heights in both the corrugated cardboard sleeve option and the plastic corrugated sleeve option. Some sizes will have an option for a drop door for easier access into the container. We currently have the following footprints available while supplies last, with a corrugated cardboard, split sleeve option: 57” x 48”, 63” x 47”, and 70” x 48”. The split sleeve will come in two halves, making loading and unloading your container easier. With the split sleeve option, you can install one half of the sleeve and load your items into the container. When you are finished loading your items, You can install the other half sleeve. If you do not find a size that will fit your application in our selection of standard pallet pack containers we have special order sizes and custom options available upon request.

Do you have questions?

Are DuraGreen Pallet Packs right for your application? If you need assistance choosing a style and size, contact Kasey or any of our account managers by calling us at 1-800-257-5560 or contact us and send us a message.