Sleeve Pack Shipping Systems and Their Rising Popularity in Supply Chain Management

Sleeve Pack Shipping Systems and Their Rising Popularity in Supply Chain Management

Reusable bulk containers, particularly the corrugated plastic sleeve pack or ‘pallet pack’, are becoming an increasingly popular choice for companies looking to optimize their supply chain processes. Initially establishing traction in Europe, this innovative form of packaging is now gaining ground in North America as its numerous advantages over traditional packaging methods become more widely recognized. Offering flexibility, cost-effectiveness, and an eco-friendly alternative to expendable packaging, sleeve packs present an appealing solution for a diverse range of applications.

What is a sleeve pack?

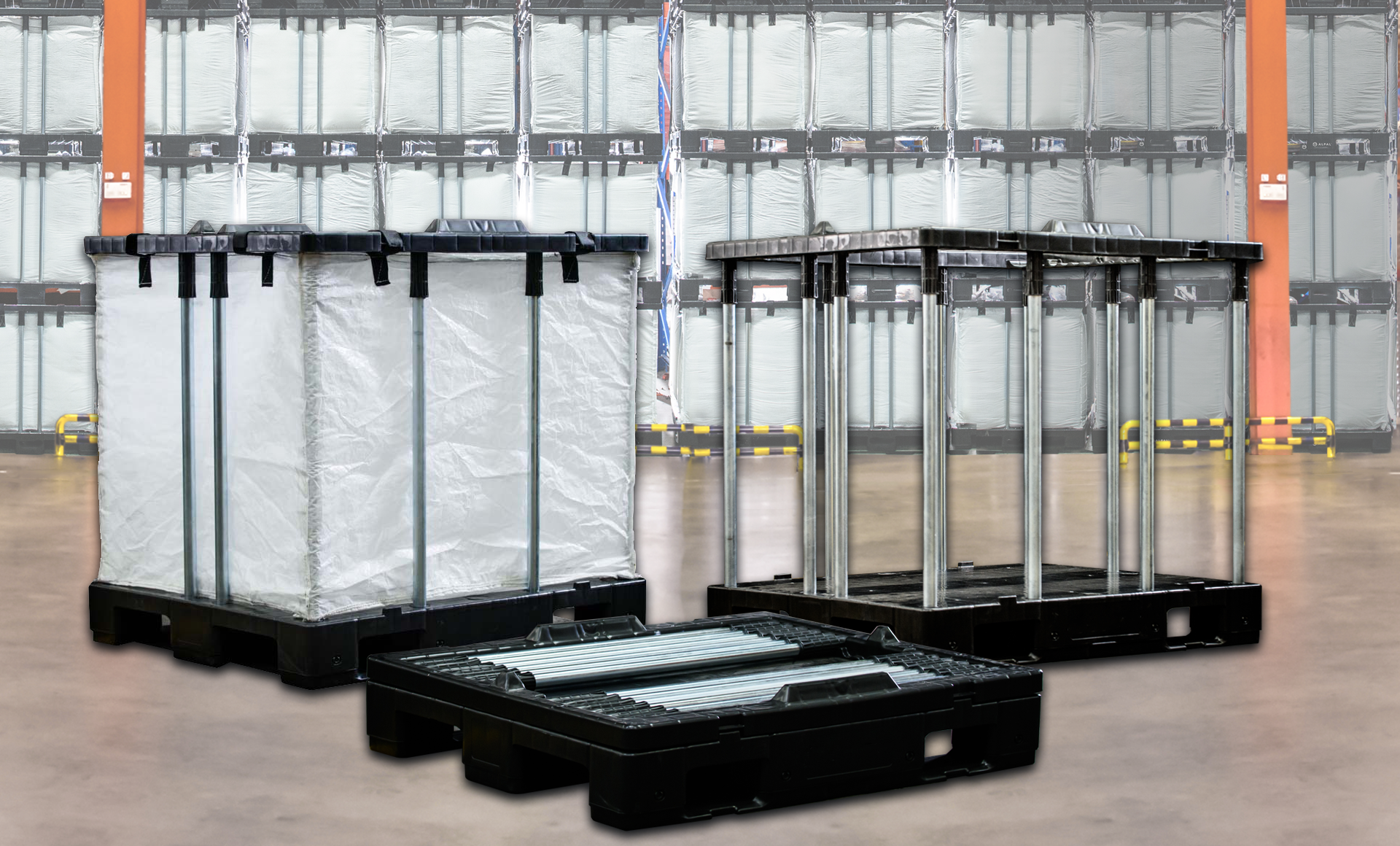

A sleeve pack is essentially a unit load shipping system designed to support, store, protect, transport, and merchandise unit loads of goods or materials. It consists of a pallet base, a top lid, and a foldable sleeve. Typically, the pallet and top lid are made of plastic, while the sleeve can be either corrugated cardboard or plastic, with the thickness varying according to the requirements of the specific application.

Sleeve packs evolved from the traditional cardboard ‘gaylord’ boxes set on wood pallets. The advent of solid deck plastic pallets eliminated the need for a bottom cardboard layer, paving the way for the introduction of sleeves – initially corrugated paper, and subsequently, hollow sheet plastic.

Despite their wide use in Europe, sleeve packs remain an underexplored opportunity in North America. Experts suggest that the benefits of these shipping systems have not been fully communicated or understood by the material handling industry.

What are the advantages?

The advantages of reusable sleeve packs over single-trip gaylord and pallet systems are numerous. In closed loops, they offer a functionally equivalent solution at a significantly lower cost per use. They are lightweight, durable, and collapsible when empty, providing efficient storage and impressive return ratios of 6:1 or even 8:1. Some international pooling applications have reported an outstanding 10:1 return ratio.

Moreover, this packaging approach allows for optimal utilization of space – it provides maximum inner dimension capacity relative to its outer dimension. Depending on the product, loaded sleeve packs can be stacked up to four high in the warehouse, and two high for shipment.

Apart from their light weight and durability, they offer customization possibilities and operator convenience. They are frequently used with thermoformed pallets as opposed to injection molded pallets, enabling faster prototyping to various pallet sizes as required. The sleeves can also be used with other types of pallets, including wood and injection molded, where a stiffer base is required.

As supply chain operations seek to increase speed and efficiency, reusable sleeve packs are being designed for quick and easy assembly and disassembly. Another significant advantage is the reduction of single-use packaging waste – sleeve packs are fully recyclable at the end of their life cycle, contributing to environmental sustainability.

What options are available in sleeve packs?

In response to varying customer needs, sleeve pack vendors offer a range of options, including drop doors, bottom doors, different locking and latching mechanisms, customized internal dunnage, graphics, colors, and a choice of sleeve materials and thicknesses.

In conclusion, the reusable sleeve pack represents a versatile, cost-effective, and sustainable solution for supply chain management. As businesses continue to seek ways to optimize their operations, the adoption of this innovative packaging system is set to grow.

Originally published by Rick Leblanc June 15, 2023 on REUSABLE PACKAGING NEWS